CAPRI

Cognitive automation platform for the digital transformation of Europe's process industry.

Total budget: 7.050.276,25 €

Description:

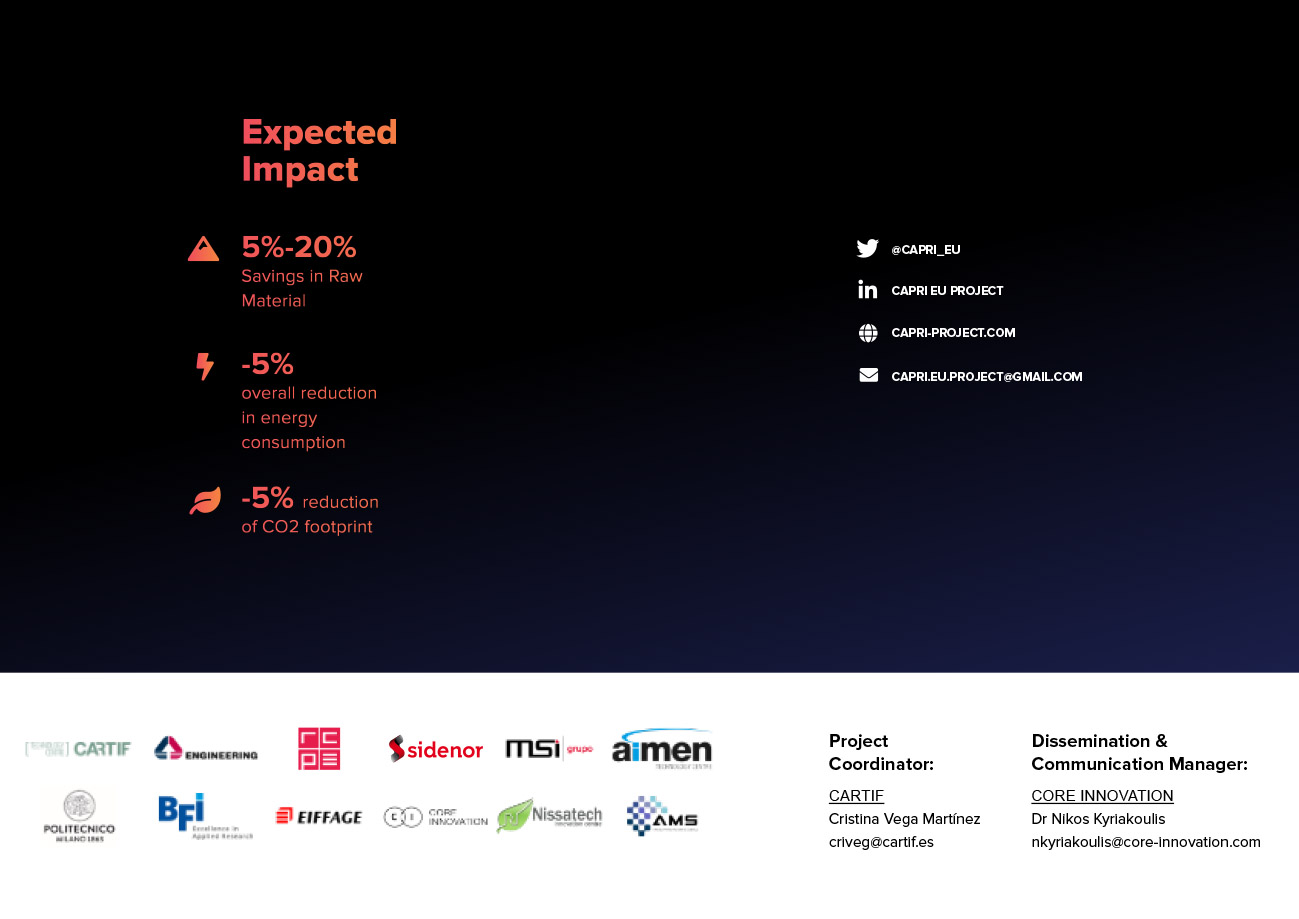

The Capri project, funded by the European Commission through the Horizon 2020 programme with 6.1 million euros and coordinated by the CARTIF Foundation, is working on the development and validation of an innovative Cognitive Automation Platform (CAP) for industrial processes.

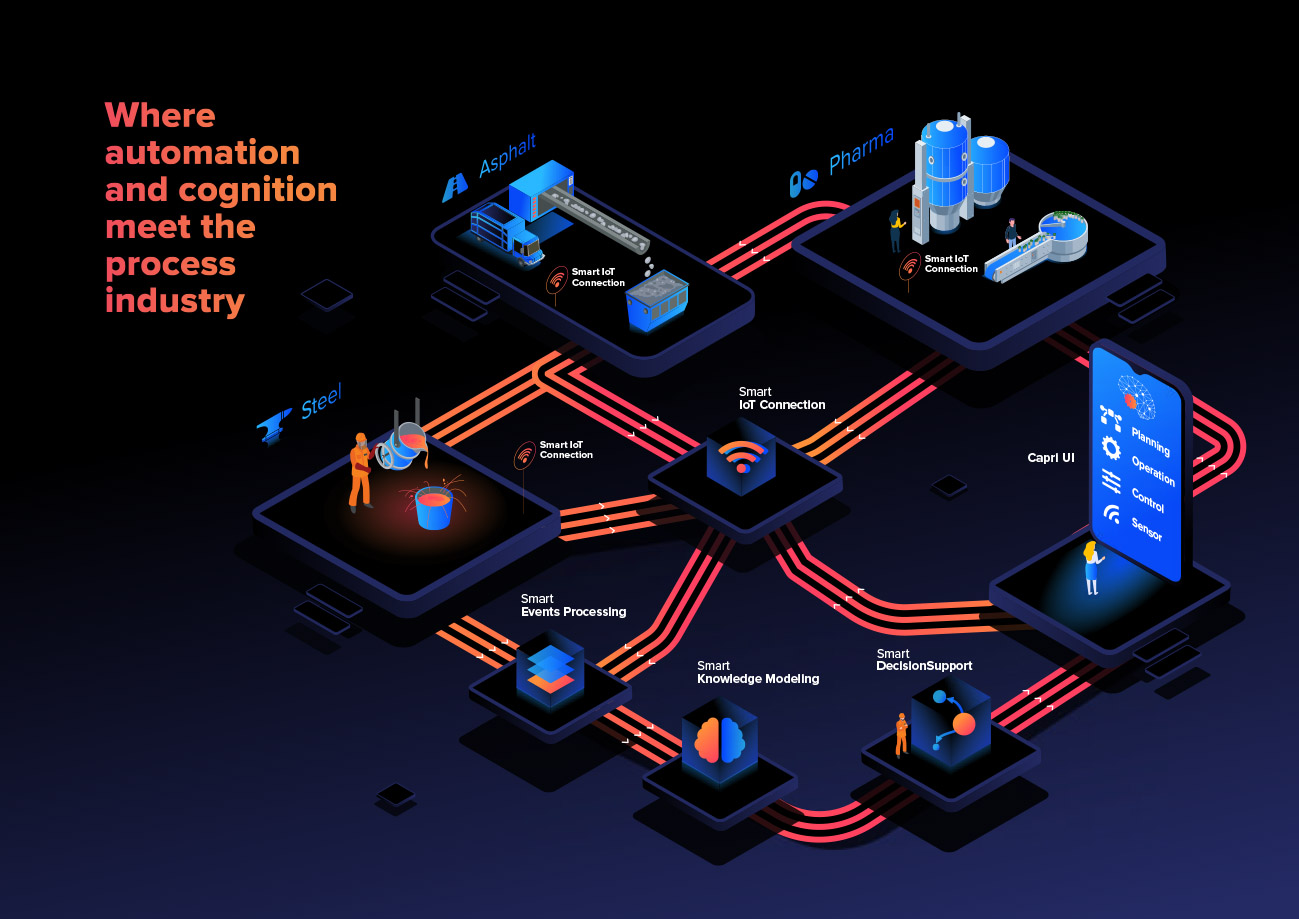

This initiative will develop, test and validate an innovative Cognitive Automation Platform that will enable intelligent automation of industrial processes. It is based on four levels of machine-operator interaction: IoT, activity processing, knowledge data modelling and intelligent decision support.

The Cognitive Automation Platform digitally interrelates and synchronises the control, operation and planning information of production plants, enabling autonomous and integrated operation of all resources. This unification is reflected in optimised management, improved performance and flexibility, and the design and deployment of new business models.

Capri will bring cognitive solutions to each key stage of the manufacturing process and will be modular and scalable so that advanced applications can be integrated into the platform. Validation of the developed technologies will be carried out by addressing manufacturing challenges in the process industry in three use cases, steel, asphalt and pharmaceutical sectors.

In this sense, EIFFAGE participates as a demonstrator, the main objective being the improvement of the performance and production flexibility of the asphalt and paving sector through a digital transformation of all the resources involved in the process. This productive improvement involves a reduction in energy consumption, an optimisation of the use of raw materials and a reduction of waste.

To this end, the digitisation of all phases of the process is proposed. This digitisation will provide the necessary analysis capacity to be able to carry out high-level supervised intelligent control to define and execute the asphalt plant’s manufacturing strategy. The new asphalt manufacturing strategy will respond in real time to fluctuations in demand for asphalt on the construction site, optimising production, improving the plant’s flexibility and guaranteeing the quality of the end product, the bituminous mix, at the time of paving at all times.

This project receives funding from the European Union’s Horizon 2020 Research and Innovation Programme. Programme under grant agreement number 870062.