Asphalt and Road Maintenance department.

Whether for new construction or rehabilitation, Eiffage Construcción team is involved in the construction and maintenance of the Spanish road network, both on local and national roads, on public or private property.

We are the undisputed national leader in the manufacture of asphalt mixtures.

Asphalt and Road Maintenance department.

Whether for new construction or rehabilitation, Eiffage Construcción team is involved in the construction and maintenance of the Spanish road network, both on local and national roads, on public or private property.

We are the undisputed national leader in the manufacture of asphalt mixtures.

Asphalt and Road Maintenance department.

Whether for new construction or rehabilitation, Eiffage Construcción team is involved in the construction and maintenance of the Spanish road network, both on local and national roads, on public or private property.

We are the undisputed national leader in the manufacture of asphalt mixtures.

IN-SITU COLD RECYCLING

In-situ cold recycling consists of crushing one or more layers of the pavement and spreading and compacting this material with pre-treatment using asphalt emulsions and/or cement and often a mixture of aggregates with a certain particle size.

Cold recycling “in situ” allows the use of deteriorated pavement materials without transferring them to the manufacturing plant. A quick treatment that is carried out on the road itself using special equipment and without the need to heat the materials.

We reuse 100 % of the deteriorated pavement layer, achieving a homogeneous and renewed pavement layer.

Advantages:

- Minimisation of the need for new binders and aggregates by reusing 100% of the aged pavement.

- Reduction of screed, verges and minimisation of the effect on the gauge, kerbs, etc., resulting in additional savings.

- Recycling with emulsion improves the shape and evenness of the existing pavement.

- Limitation of traffic interference. Almost immediate opening to traffic.

- Savings in time, raw materials and labour. Reduced environmental impact: minimises energy consumption by eliminating the need to extract aggregate, manufacture new mixes at the plant and transport them to the site.

IN-SITU COLD RECYCLING

In-situ cold recycling consists of crushing one or more layers of the pavement and spreading and compacting this material with pre-treatment using asphalt emulsions and/or cement and often a mixture of aggregates with a certain particle size.

Cold recycling “in situ” allows the use of deteriorated pavement materials without transferring them to the manufacturing plant. A quick treatment that is carried out on the road itself using special equipment and without the need to heat the materials.

We reuse 100 % of the deteriorated pavement layer, achieving a homogeneous and renewed pavement layer.

Advantages:

1- Minimisation of the need for new binders and aggregates by reusing 100% of the aged pavement.

2- Reduction of screed, verges and minimisation of the effect on the gauge, kerbs, etc., resulting in additional savings.

3- Recycling with emulsion improves the shape and evenness of the existing pavement.

4- Limitation of traffic interference. Almost immediate opening to traffic.

5- Savings in time, raw materials and labour. Reduced environmental impact: minimises energy consumption by eliminating the need to extract aggregate, manufacture new mixes at the plant and transport them to the site.

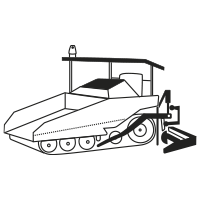

SILO DE TRANSFERT

The mobile transfer silo is able to store agglomerate with a particularity that makes it unique: it can decouple the paver from the trucks and guarantee a regular and non-stop advance and a reduction of the precise number of trucks, achieving a very high homogeneity, eliminating thermal and granulometric segregations.

The advantages of using a transfer silo are:

- Achieving homogeneity of the mix after arrival on site by remixing it before adding it to the paver.

- Achieve adequate values and IRI’s.

- Reducing the number of lorries used for transport by reducing the waiting time on site.

- Doubling the usual production of a paving equipment by up to 30%.

- Possibility of working continuously without stops and at a constant speed, without being hit by trucks and with a constant flow of mix to the screed.

SILO DE TRANSFERT

The mobile transfer silo is able to store agglomerate with a particularity that makes it unique: it can decouple the paver from the trucks and guarantee a regular and non-stop advance and a reduction of the precise number of trucks, achieving a very high homogeneity, eliminating thermal and granulometric segregations.

The advantages of using a transfer silo are:

1- Achieving homogeneity of the mix after arrival on site by remixing it before adding it to the paver.

2- Achieve adequate values and IRI’s.

3- Reducing the number of lorries used for transport by reducing the waiting time on site.

4- Doubling the usual production of a paving equipment by up to 30%.

5- Possibility of working continuously without stops and at a constant speed, without being hit by trucks and with a constant flow of mix to the screed.

RUMBLE STRIPS

Rumble strips created on site with a W-35 DC milling machine, using an accessory that programmes the width, length, depth and shape of the stripe in the pavement. Cant adjustment using the Wirtgen levelling system.

Avantages

It is an effective road safety measure to prevent road accidents and provides numerous advantages:

- Noise and vibration effectiveness

- Solution especially suitable for heavy vehicles.

- The rumble strip has the same durability as the wearing course.

- Minimal or no maintenance.

- Very competitive cost compared to current struder/vibroline rumble strips.

- Increased road safety in winter periods as the rumble strip is not damaged by the passage of snow ploughs.

- Greater visibility of the track with the longitudinal paint.

- The vibration of the vehicle that produces the rumble strip acts as a guide when visibility is very low (fog, snow, ice…) thus increasing its effectiveness.

RUMBLE STRIPS

Rumble strips created on site with a W-35 DC milling machine, using an accessory that programmes the width, length, depth and shape of the stripe in the pavement. Cant adjustment using the Wirtgen levelling system.

Avantages

It is an effective road safety measure to prevent road accidents and provides numerous advantages:

1- Noise and vibration effectiveness

2- Solution especially suitable for heavy vehicles.

3- The rumble strip has the same durability as the wearing course.

4- Minimal or no maintenance.

5- Very competitive cost compared to current struder/vibroline rumble strips.

6- Increased road safety in winter periods as the rumble strip is not damaged by the passage of snow ploughs.

7- Greater visibility of the track with the longitudinal paint.

8- The vibration of the vehicle that produces the rumble strip acts as a guide when visibility is very low (fog, snow, ice…) thus increasing its effectiveness.

CRACK SEALING

Solutions to ensure the highest possible level of safety.

Crack sealing is one of the most interesting ways of keeping roads in good condition and guaranteeing the highest possible level of traffic safety.

At Eiffage Construcción, we have been developing our skills in this area for over 50 years and have proven our ability to respond to the demands of infrastructure, being one of the leading companies when it comes to producing and applying paving materials. We can work with or without lane closures and on all types of roads.

We know that the more deterioration there is in the existing asphalt, the greater the investment that will have to be made in the future. Crack sealing delays the ageing of the pavement by at least five years at minimal cost to the community.

CRACK SEALING

Solutions to ensure the highest possible level of safety.

Crack sealing is one of the most interesting ways of keeping roads in good condition and guaranteeing the highest possible level of traffic safety.

At Eiffage Construcción, we have been developing our skills in this area for over 50 years and have proven our ability to respond to the demands of infrastructure, being one of the leading companies when it comes to producing and applying paving materials. We can work with or without lane closures and on all types of roads.

We know that the more deterioration there is in the existing asphalt, the greater the investment that will have to be made in the future. Crack sealing delays the ageing of the pavement by at least five years at minimal cost to the community.

SOIL CEMENT

Structural strength of the pavement.

Soil cement is defined as a homogeneous mixture in the appropriate proportions of granular material, cement and water, and possibly additives, which, when suitably compacted, is used as the structural layer of a pavement. Soil-cement is normally used as a sub-base for other materials treated with cement, or as a base for other bituminous layers. In the latter case, it provides the structural strength of the pavement.

At Eiffage Construcción we have been working for more than 50 years in a wide range of pavement recycling and soil stabilisation processes, committed to quality and full customer satisfaction.

We offer all our experience to advise our clients on any technical-economic aspect of soil cement.

SOIL CEMENT

Structural strength of the pavement.

Soil cement is defined as a homogeneous mixture in the appropriate proportions of granular material, cement and water, and possibly additives, which, when suitably compacted, is used as the structural layer of a pavement. Soil-cement is normally used as a sub-base for other materials treated with cement, or as a base for other bituminous layers. In the latter case, it provides the structural strength of the pavement.

At Eiffage Construcción we have been working for more than 50 years in a wide range of pavement recycling and soil stabilisation processes, committed to quality and full customer satisfaction.

We offer all our experience to advise our clients on any technical-economic aspect of soil cement.

ROAD SURFACES, PAVEMENTS AND ASPHALTS

Solutions for all roads, for all projects.

Eiffage Construcción contributes to the quality of the road and infrastructure network throughout Spain. We carry out everything from remodelling road networks to paving operations, in both urban and rural areas, for public and private clients. Eiffage Construcción is committed to innovative solutions and processes that guarantee a high level of service at a controlled cost. All with a real concern for reducing the ecological footprint.

Our technical teams are able to define, on a case by case basis, the optimal solution according to the needs of companies and communities.

ROAD SURFACES, PAVEMENTS AND ASPHALTS

Solutions for all roads, for all projects.

Eiffage Construcción contributes to the quality of the road and infrastructure network throughout Spain. We carry out everything from remodelling road networks to paving operations, in both urban and rural areas, for public and private clients. Eiffage Construcción is committed to innovative solutions and processes that guarantee a high level of service at a controlled cost. All with a real concern for reducing the ecological footprint.

Our technical teams are able to define, on a case by case basis, the optimal solution according to the needs of companies and communities.

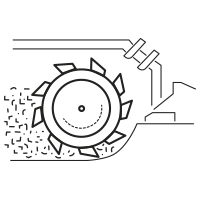

MILLING AND MICRO-MILLING

Our milling department is a pioneer in Spain in the provision of milling services, with more than 25 years of service.

After a preliminary study of the pavement to be rehabilitated, the sections to be milled are defined. Milling makes it possible to remove the defective parts of the pavement without touching those that are in good condition. With a single machine and in a single pass, the desired length, width and thickness are removed and loaded directly onto the lorry. Working times are considerably reduced with minimal impact on traffic. The resulting milled material can be reused for the manufacture of new asphalt mixtures or as selected or suitable soil on site. Our service includes the sweeping of the milled area by means of self-loading sweepers that perform an excellent sweeping.

Milling is a fundamental stage in the rehabilitation of deteriorated asphalt pavements.

MILLING AND MICRO-MILLING

Our milling department is a pioneer in Spain in the provision of milling services, with more than 25 years of service.

After a preliminary study of the pavement to be rehabilitated, the sections to be milled are defined. Milling makes it possible to remove the defective parts of the pavement without touching those that are in good condition. With a single machine and in a single pass, the desired length, width and thickness are removed and loaded directly onto the lorry. Working times are considerably reduced with minimal impact on traffic. The resulting milled material can be reused for the manufacture of new asphalt mixtures or as selected or suitable soil on site. Our service includes the sweeping of the milled area by means of self-loading sweepers that perform an excellent sweeping.

Milling is a fundamental stage in the rehabilitation of deteriorated asphalt pavements.

ROAD MAINTENANCE AND SERVICES

Every year, our group is involved in many road network maintenance and upkeep operations: local roads, major motorways, rest areas and logistics platforms, both public and private. The objective is to contribute in all areas to improving the quality of road networks and infrastructures. The scope of action of this area applies to the maintenance and optimisation of existing infrastructures through service contracts or improvement works. We currently carry out maintenance work for the large state administrations, in autonomous regions and in various urban maintenance projects.

ROAD MAINTENANCE AND SERVICES

Every year, our group is involved in many road network maintenance and upkeep operations: local roads, major motorways, rest areas and logistics platforms, both public and private. The objective is to contribute in all areas to improving the quality of road networks and infrastructures. The scope of action of this area applies to the maintenance and optimisation of existing infrastructures through service contracts or improvement works. We currently carry out maintenance work for the large state administrations, in autonomous regions and in various urban maintenance projects.

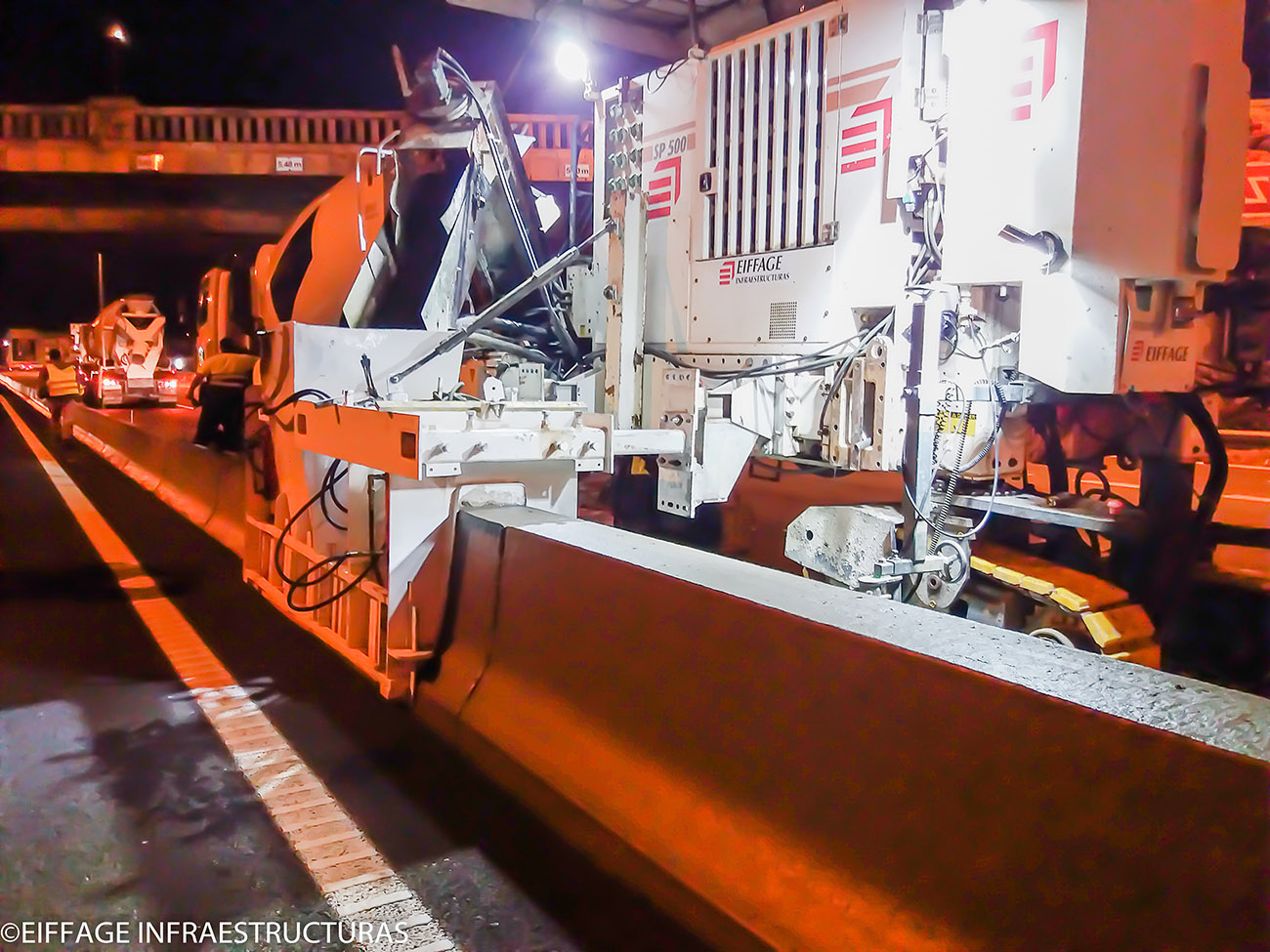

EXTRUDED CONCRETE

· Rigid SAFETYBAR concrete barriers with CE marking: Construction of rigid concrete barriers “in situ”. New Jersey type, single and double-sided. High rate of installation, more than 1 m/minute.

· Concrete pavements:Airports, streets.

· Continuous concrete slabs:Airports wireways, ditches…

· Drainage ditches: Concrete pipe with longitudinal groove for rainwater collection. Machinery Directory. On-site construction of: 300 mm and 400 mm ditches, kerbs of all types and sizes.

EXTRUDED CONCRETE

· Rigid SAFETYBAR concrete barriers with CE marking: Construction of rigid concrete barriers “in situ”. New Jersey type, single and double-sided. High rate of installation, more than 1 m/minute.

· Concrete pavements:Airports, streets.

· Continuous concrete slabs:Airports wireways, ditches…

· Drainage ditches: Concrete pipe with longitudinal groove for rainwater collection. Machinery Directory. On-site construction of: 300 mm and 400 mm ditches, kerbs of all types and sizes.

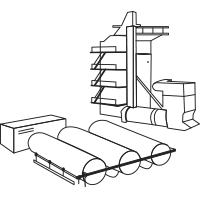

MOBILE ASPHALT PLANTS

In view of the worldwide need for infrastructures for economic development, Eiffage Construcción, leader in the manufacture of asphalt mixes at national level, has mobile asphalt plants for the manufacture and laying of asphalt mixes in order to satisfy the existing demand at international level.

Construction companies, experts in the development of large infrastructure projects, are faced with the need to find the ideal partner to meet their needs in the execution of projects that arise anywhere in the world. For this reason, Eiffage Construcción asphalt plants operate both nationally and internationally. We also have a Machinery Department and Technical Teams ready to be mobilised anywhere in the world.

In view of the worldwide need for infrastructures for economic development, Eiffage Construcción, leader in the manufacture of asphalt mixes at national level, has mobile asphalt plants for the manufacture and laying of asphalt mixes in order to satisfy the existing demand at international level.

- Technical advice for the execution of any type of work.

- Collaboration, advice and proposals, based on our extensive experience, of alternative solutions that can lead to improvements in costs, quality, safety, environment and/or reduction of execution time.

- Within the collaboration possibilities, we offer a training service and even the application of some special products where the execution is complex or key to the completion of the work (aesthetics and/or structural functions).

- Annex to the general project for the establishment of the plant/s in order to obtain the necessary permits.

- Complete assembly and disassembly of the plant(s) on site including transport.

- Design of products according to project specifications.

- Purchase of the necessary raw materials.

- Complete management of the plant/s: Production and Logistics.

- Transport of the product, paving and application on site, both for concrete and asphalt.

Asphalt and Road Maintenance department. asfaltoycv.eii.spain@eiffage.com +34 954610400

MOBILE ASPHALT PLANTS

In view of the worldwide need for infrastructures for economic development, Eiffage Construcción, leader in the manufacture of asphalt mixes at national level, has mobile asphalt plants for the manufacture and laying of asphalt mixes in order to satisfy the existing demand at international level.

Construction companies, experts in the development of large infrastructure projects, are faced with the need to find the ideal partner to meet their needs in the execution of projects that arise anywhere in the world. For this reason, Eiffage Construcción asphalt plants operate both nationally and internationally. We also have a Machinery Department and Technical Teams ready to be mobilised anywhere in the world.

Eiffage Construcción provides its mobile installations on site for the production of asphalt mixes with a comprehensive service:

1.-Technical advice for the execution of any type of work.

2.- Collaboration, advice and proposals, based on our extensive experience, of alternative solutions that can lead to improvements in costs, quality, safety, environment and/or reduction of execution time.

3.-Within the collaboration possibilities, we offer a training service and even the application of some special products where the execution is complex or key to the completion of the work (aesthetics and/or structural functions).

4.-Annex to the general project for the establishment of the plant/s in order to obtain the necessary permits.

5.-Complete assembly and disassembly of the plant(s) on site including transport.

6.- Design of products according to project specifications.

7.-Purchase of the necessary raw materials.

8.-Complete management of the plant/s: Production and Logistics.

9.-Transport of the product, paving and application on site, both for concrete and asphalt.

Asphalt and Road Maintenance department. asfaltoycv.eii.spain@eiffage.com +34 954610400